just back from a week's vacation, despite disconnecting the 12v battery, and despite charging it up a few hours right before leaving, it was down to 5v when I returned... Not a problem with the car, just a weak battery. It should be able to sit disconnected for a week without going dead. Anyway, I've found I can easily jump-start it by touching a quarter across the DC/DC contactor, which sends 13v from the 160v main pack to the aux battery and gets everything up and running.

In other news, I've begun tearing the upper motor mounts a little bit. A redesign has already happened in my head, just need to make it happen in the car now... Basically I want to replace the upper mounts which are simple cylindrical rubber vibration isolation mounts with the original beefy rubber engine mount that was in the car. I've ordered the parts I need, but it will require fabricating a new end plate to connect the motor to the new mount. And will require pulling the motor/trans out again. That's ok, there's a few other things I want to do in there too that will be a lot easier with it all out.

Next update will probably be in a few weeks, I'm not going to tear it apart until after the new year, and after I have a chance to get the Big Red Van's transmission looked at (it's slipping a bit). In the meantime, I've lowered the motor amps to 350a to save from doing more damage to the upper mount.

Thursday, December 29, 2011

Thursday, December 8, 2011

a few little updates... It's been running well, the heater has been fine even in the cold 30 degree mornings lately. And that's just with one element switched on. I can't imagine needing the second one! Though it is garage kept right now, which helps keep it not as cooold overnight. Less to have to warm up.

Anyway, I've been tracking my ah/mile (amp hours per mile) through the controller lately, and I've noticed about a 10% difference between the 30 degree morning run to school, and the 55 degree afternoon pickup. All else is pretty equal but the temp. Not too surprising, batteries don't really like cold weather. Even worse case usage, I've still got an easy 45 mile range without flattening the batteries (you really aren't supposed to take them further than 80% discharged) which is plenty for my daily routine. Best case in the summer should be closer to 60 or so miles.

yesterday I wired the brake vacuum pump through a toggle switch so I can shut it off in parking lots for that cool 'silent EV effect' and for those times when the pump sticks on... I plan to do the same to the motor blower, but it's not nearly as noisy so I'm not feeling quite as urgent about it.

it's getting driven between 20-40 miles every day right now, charging up for what I calculate to be the equivalent of ~$1.30/gallon when normalized against the Honda Odyssey it replaced. And working just fine as my main kid transporter! And this is paying a pretty high $.24/kWh with PG&E, should be able to pretty easily cut this in at least half with either solar, or a dedicated E9 rate meter, or both. Down the road a bit for those...

Anyway, I've been tracking my ah/mile (amp hours per mile) through the controller lately, and I've noticed about a 10% difference between the 30 degree morning run to school, and the 55 degree afternoon pickup. All else is pretty equal but the temp. Not too surprising, batteries don't really like cold weather. Even worse case usage, I've still got an easy 45 mile range without flattening the batteries (you really aren't supposed to take them further than 80% discharged) which is plenty for my daily routine. Best case in the summer should be closer to 60 or so miles.

yesterday I wired the brake vacuum pump through a toggle switch so I can shut it off in parking lots for that cool 'silent EV effect' and for those times when the pump sticks on... I plan to do the same to the motor blower, but it's not nearly as noisy so I'm not feeling quite as urgent about it.

it's getting driven between 20-40 miles every day right now, charging up for what I calculate to be the equivalent of ~$1.30/gallon when normalized against the Honda Odyssey it replaced. And working just fine as my main kid transporter! And this is paying a pretty high $.24/kWh with PG&E, should be able to pretty easily cut this in at least half with either solar, or a dedicated E9 rate meter, or both. Down the road a bit for those...

Tuesday, November 29, 2011

New stereo

I did a little 'fun' work on the car last night, installed a new stereo and put on a few decals. It had an am/fm cassette, but since installing the new controller, the radio had so much interference I couldn't use it while driving. I tried a Droidx to cassette adapter, but the radio ate the adapter... I pulled the radio out and destroyed it to retrieve my adapter (which works fine in my van, so I wanted to keep it). The new stereo came from Crutchfield, basically just a cheap-ish unit that allows bluetooth. I don't so much care about the phone, I never really have a need to talk on the phone while driving, but I wanted to be able to stream Pandora over bluetooth from the Droidx.

As it turns out, I now have no interference on FM, and only a little bit on AM. I took great care in getting good chassis grounds (instead of grounding through the factory harness), maybe that helped? Anyway, I'm super happy about having radio reception again!

In this pic you can see the bluetooth dongle (it's not integrated directly into the unit) on the left side of the photo. Once again I'm super happy with Crutchfield, and their installation kits. Pretty much plug and play, just had to solder the wires from the supplied car adapter to the radio pigtail. The plastic bezel and little pocket above the radio fit great, and the texture even matches the stock panels.

the following pic shows a more overall shot. I've temporarily removed the pack volt and amp gauges (they used to be where the Droid mount is) because I didn't like them there. I'll either re-install them on the A-pillar (that's where they are on my van, I'm used to it...) or go with a 'virtual' display over the Droid. I'm still investigating my options there, but in the meantime I can either use a laptop on the passenger seat connected to the Synkromotive, or just drive blind (which is what I've been doing for the last few days). There's plenty of safety systems in place to keep the pack safe, I don't really NEED the gauges. But I do like having them.

And here's the new decals. The 'high voltage' and symbols on the left side are basically there to cover up a decal from the original selling dealer. The 'electric' emblem looks pretty good, I think! Still pretty subtle.

As it turns out, I now have no interference on FM, and only a little bit on AM. I took great care in getting good chassis grounds (instead of grounding through the factory harness), maybe that helped? Anyway, I'm super happy about having radio reception again!

In this pic you can see the bluetooth dongle (it's not integrated directly into the unit) on the left side of the photo. Once again I'm super happy with Crutchfield, and their installation kits. Pretty much plug and play, just had to solder the wires from the supplied car adapter to the radio pigtail. The plastic bezel and little pocket above the radio fit great, and the texture even matches the stock panels.

|

| From 2011-11-29 stereo |

|

| From 2011-11-29 stereo |

|

| From 2011-11-29 stereo |

Friday, November 18, 2011

It's been about a week, not much to really update... Car's been running great, I've been driving it every day. Between 20-40 miles/day, charging overnight. I did do a few small things; moved the motor blower to an isolated mount, removed the radio (it ate my ipod tape adapter, so I forcibly removed it!), and installed a shoulder harness for the middle backseat seatbelt so I can now carpool 4 kids to school.

I am having a little problem with the vacuum pump (the pump keeps the vacuum for the power brakes up), it sometimes doesn't shut off. I've found that a sharp 'whack' to the side of the pump does it, so it must just be a sticky pressure switch (the pump has an internal pressure switch). I want to move the pump to the same isolated mount that the motor blower is on, I'll pull it apart and see if I can clean up the switch while I've got it out.

I am having a little problem with the vacuum pump (the pump keeps the vacuum for the power brakes up), it sometimes doesn't shut off. I've found that a sharp 'whack' to the side of the pump does it, so it must just be a sticky pressure switch (the pump has an internal pressure switch). I want to move the pump to the same isolated mount that the motor blower is on, I'll pull it apart and see if I can clean up the switch while I've got it out.

Tuesday, November 8, 2011

range update

just a little range update here... last night I did 27 miles up to a meeting and back, Most of those miles were at 65 mph on the freeway. It was about 40 degrees F out, and I used the heater about 1/2 the time (1500w electric element). It re-charged for ~10 hours at 5.8a last night, about 60ah.

If I assume I don't want to go below 80% dod (depth of discharge, which would be 104ah of my 130ah pack) then I have a freeway range of about 46 miles. A bit more if I don't need the heater. I'll round it up to 50 miles and call it good. It should do even better in warmer weather.

As an aside, for a 15 year old car with over 130k on the chassis, this thing rides smooth! It's nice and quiet on the freeway at 65 in 4th gear, no vibes or anything.

If I assume I don't want to go below 80% dod (depth of discharge, which would be 104ah of my 130ah pack) then I have a freeway range of about 46 miles. A bit more if I don't need the heater. I'll round it up to 50 miles and call it good. It should do even better in warmer weather.

As an aside, for a 15 year old car with over 130k on the chassis, this thing rides smooth! It's nice and quiet on the freeway at 65 in 4th gear, no vibes or anything.

Sunday, November 6, 2011

more pictures

Things are looking good! I installed the Evnetics TPS and the Netgain speed sensor, and rewired the vacuum pump to be on a relay. All went well, I went for a 10 mile or so test drive and had no cutouts or faults. I did lots of experimenting with settings, I’ve settled (at least for now) on 400a battery side and 750a motor side. I’ll just rely on my judgement and right foot control to keep from spinning tires or breaking CV joints… Anyway, with only 400a from the battery I’m not able to get 750a for long at all off the line, but it starts high, then holds over 600a for a while (up to about 2000rpm or so). With these settings it’s pretty quick off the line, and certainly fast enough for daily driving with a little fun when desired. I will still hit a low voltage alarm on the MiniBMS if I try to sustain more than 300ish amps for too long, so I set the low voltage ‘soft’ limit to 135 volts in the Synkromotive software. This lets me use up to 400a briefly, and the controller will taper it back for me when needed. It seems to work well, I did some intentionally hard pulls and never heard the alarm after setting this limit. I never felt any kind of cutback, the controller handles it smoothly. I’ll have to go back to my test road soon and re-test the 0-60.

here's a bunch of photo's from the weekend:

the old potbox

the custom cable holder. just a simple piece of sheetmetal bent and drilled to hold the nub on the end of the cable. the holes in the TPS bracket are already the perfect size for this, so the cable is sandwiched between the arm and this little bracket. each side holds the nub, and it's free to rotate. simple and effective.

here is the arm with the cable attached

here's the whole throttle assembly attached. it is truly a piece of beauty! I'm not sure my car is worthy of such a nice part. it certainly deserves a nicer mounting bracket...

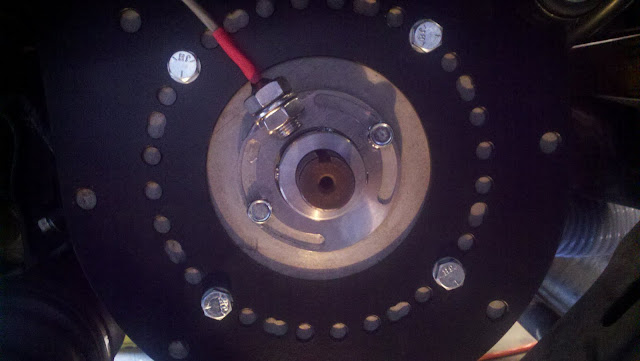

here is the Netgain speed sensor. Very easy to install, the only challenging part was that my motor endshaft had just enough surface rust on it to keep the collar from sliding on. i had to remove the wheel to get better access, then lightly sand the shaft with some 600 grit paper to smooth it up enough to install the collar. although looking at this photo, i can see that I accidentally lined up one of the set screws with the keyway. dang, I'll have to get back in there and rotate it a bit.

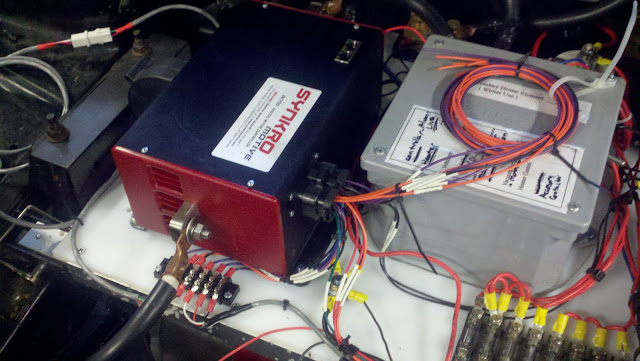

here's the controller! the small terminal block right in front of it holds the connections to the speed sensor and the throttle. The bundle of wires on my heater controls box are the extra wires not needed for my installation (reversing contactor controls, various outputs, etc). Not sure what to do with those yet... all the wires plug into the controller with a nice waterproof connector, which seems a little odd since the controller itself is obviously not waterproof. Anyway, the wires were all nice and long, easy to route and connect up.

here's the backside. Yes, I'm using a second EV200 contactor for my high voltage accessories. Yes, it's overkill.

and the overall shot. this is pretty much finished up. You can see the 12v relay next to the terminal strips, that's for the vacuum pump. The loose wires heading down in the front of the photo are going to the motor blower. I still need to clean up and re-route those wires.

That's it for now. Hopefully it will stay this way for a little while. I do need to put on some of the plastic bits back on up front to get it ready for the rain, but it's basically ready to be my daily driver now.

here's a bunch of photo's from the weekend:

the old potbox

|

| From 2011-11-06 synkro |

the custom cable holder. just a simple piece of sheetmetal bent and drilled to hold the nub on the end of the cable. the holes in the TPS bracket are already the perfect size for this, so the cable is sandwiched between the arm and this little bracket. each side holds the nub, and it's free to rotate. simple and effective.

|

| From 2011-11-06 synkro |

here is the arm with the cable attached

|

| From 2011-11-06 synkro |

here's the whole throttle assembly attached. it is truly a piece of beauty! I'm not sure my car is worthy of such a nice part. it certainly deserves a nicer mounting bracket...

|

| From 2011-11-06 synkro |

here is the Netgain speed sensor. Very easy to install, the only challenging part was that my motor endshaft had just enough surface rust on it to keep the collar from sliding on. i had to remove the wheel to get better access, then lightly sand the shaft with some 600 grit paper to smooth it up enough to install the collar. although looking at this photo, i can see that I accidentally lined up one of the set screws with the keyway. dang, I'll have to get back in there and rotate it a bit.

|

| From 2011-11-06 synkro |

here's the controller! the small terminal block right in front of it holds the connections to the speed sensor and the throttle. The bundle of wires on my heater controls box are the extra wires not needed for my installation (reversing contactor controls, various outputs, etc). Not sure what to do with those yet... all the wires plug into the controller with a nice waterproof connector, which seems a little odd since the controller itself is obviously not waterproof. Anyway, the wires were all nice and long, easy to route and connect up.

|

| From 2011-11-06 synkro |

here's the backside. Yes, I'm using a second EV200 contactor for my high voltage accessories. Yes, it's overkill.

|

| From 2011-11-06 synkro |

and the overall shot. this is pretty much finished up. You can see the 12v relay next to the terminal strips, that's for the vacuum pump. The loose wires heading down in the front of the photo are going to the motor blower. I still need to clean up and re-route those wires.

|

| From 2011-11-06 synkro |

That's it for now. Hopefully it will stay this way for a little while. I do need to put on some of the plastic bits back on up front to get it ready for the rain, but it's basically ready to be my daily driver now.

Friday, November 4, 2011

Synkromotive installed

|

| From 2011-11-04 controller |

I was supposed to spend the weekend in Tahoe, but it's snowing, cold, and I've been sick for a few weeks. I'm really not up for it right now, so I stayed home. On the bright side, I spent some quality time in the garage and got the Synkromotive controller installed tonight! Pretty straightforward, the hardest part was actually getting to the reverse light wire. I had to pull out the 12v battery, and battery tray to get down to it.

All the existing high voltage cables worked as is, I really didn't have to move much around at all One motor cable is now on the opposite side of the controller, but the cable length still works fine. It's just routed differently. The controller comes with all the wires pre-attached to a connector, it took a while to sort them all out and figure out what went where, and which ones I don't need. The ones I'm not using I just zip tied out of the way. Not sure what I'll do with them long term, I don't really want to cut them off permanently. The ones I do need, I just went one at a time, and took my time connecting them where they need to go.

Anyway, I don't have the new throttle position sensor yet, so I just wired in the existing two wire potbox that's in the car. Not ideal, but it will work.

With the main pack disconnected, I powered up the controller and hooked it up to a laptop with the Synkro software installed on it. It just plugs into a USB port, the program recognized the controller when it opened up and everything looked alright. The interface is sweet, just simple and easy to use. I set the battery parameters then calibrated the pot box. So far so good! I flipped on the main pack breaker, and went for the full test. Car in neutral, one hand turning on the key, and the other holding the cord to trip the breaker. Key on, the controller's fan hummed for a few seconds then went off. The stats on the computer showed pack voltage was on. I gave it a little throttle, and there was a nice little hum as the motor slowly turned over.

After verifying everything for a little bit, I took it for a test drive. For the initial test I set the battery amps to 300, and the motor also to 300. first thing I notice is that it is SMOOOOTH!!!! Finally, I can drive it like an electric car. After a few blocks, I pulled over and bumped the motor amps up to 500 (battery still at 300). Nice! Much quicker off the line. Drove around like this a while, then decided to really go for it and bump it up to 750a. Just on the motor side, battery was still at 300. Very nice! Spun the wheels a bit in second gear. Definately faster now. In the interest of not doing anything stupid, I called it a night and came back home.

Up and into the driveway (up a hill while turning and transitioning over a driveway, it's been my nemesis for driving smoothly) without drama, I could stop and start at will. I'm liking it already! And this is with the old potbox, should get even better with the new TPS.

Thursday, November 3, 2011

charger wiring

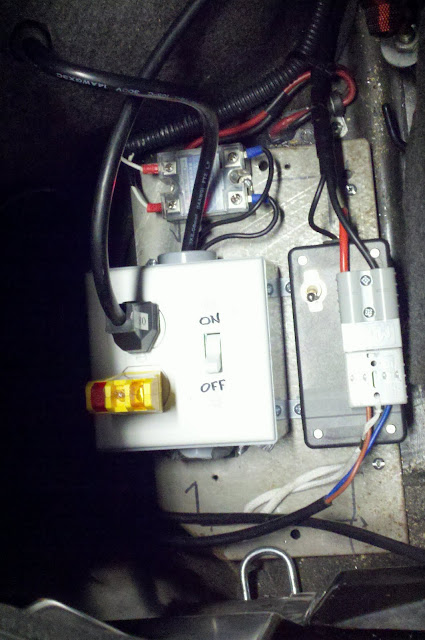

I did a little charger wiring clean up today. Nothing new functionally, just a little cleaner and easier to use. In the picture you can see the power inlet cord coming through the side from the gas tank door (upper left of the picture), one leg goes through the solid state relay controlled by the MiniBMS, then it goes into a junction box with a dual pole switch leading to an outlet. This is so I can plug the extension cord into the car without the charger being 'live' yet so I don't get arcing at the extension cord. The charger plugs into the outlet. From the charger, I then mounted the Anderson connector to a small project box that has a simple 20a rated switch with one leg of the charger output going through it. This is so I can power on the charger with the output disconnected, then just flip the switch instead of having to plug in the Anderson every time.

So, the process goes like this.

1) make sure both switches are off.

2) plug in cord to car.

3) flip switch on junction box to power charger.

4) flip switch on small box to connect output to battery pack.

So, the process goes like this.

1) make sure both switches are off.

2) plug in cord to car.

3) flip switch on junction box to power charger.

4) flip switch on small box to connect output to battery pack.

|

| From 2011-11-03 plug |

Wednesday, November 2, 2011

sloooow charger

so I drove 46 miles yesterday. Several trips throughout the day, mostly 35ish mph, some freeway. I plugged in last night, it was not charged yet this morning when I went to take the kids to school! It was probably close to 12 hours on the charger at 5.8a... guess I need to plug in earlier (or get a bigger charger...). Bummer since the charger screws with my radio reception in the house.

Friday, October 28, 2011

new controller

look what just showed up on my doorstep!

It's my new Synkromotive controller. bummer I won't have a chance to install it for a while...

|

| From 2011-10-28 synkro |

It's my new Synkromotive controller. bummer I won't have a chance to install it for a while...

Monday, October 24, 2011

alarming

I blipped the low voltage alarm on the MiniBMS this morning (the MiniBMS is an individual battery monitoring system. Each cell has a circuit board on it and they are all connected together to a master board that keeps track of their voltages and reports any problems). I was accelerating onto the freeway in third gear. Basically it was a full throttle 0-60 run in 3rd gear trying to get up to speed of traffic, so probably 15 seconds at least at max throttle. I heard the alarm for just a second as I approached 60mph while pulling 300a from the batteries (48x 130ah cells). According to the numbers I can find online for my tranny and final drive ratio, 60mph in third gear is 5000rpm, so it's right up there on the high end of where I should be taking the motor. Anyway, I heard the alarm beep for just a second just as I was going to make the shift to 4th gear anyway. I was showing about 130v (153v nominal system), though it's a small analog gauge and a bit hard to read while driving (+/- 10 volts would be hard to tell).

Anyway, I should be able to pull many more amps than that without this much voltage sag, not going to worry about it quite yet, but it's something to wonder about. Hopefully it's something simple like needing bigger wiring or better connections in the battery loop. I do know that right now a few of my cables are 2awg which is awfully small. They should all be 2/0, and will be eventually once I decide exactly how I want all the batteries laid out and tied down.

Anyway, I should be able to pull many more amps than that without this much voltage sag, not going to worry about it quite yet, but it's something to wonder about. Hopefully it's something simple like needing bigger wiring or better connections in the battery loop. I do know that right now a few of my cables are 2awg which is awfully small. They should all be 2/0, and will be eventually once I decide exactly how I want all the batteries laid out and tied down.

Sunday, October 23, 2011

motor mounts

Finished up the motor end torque mount today! I think it's pretty good, you can also see the finished upper mount in these photo's,,,

I used another stock Saturn transmission torque strut just to keep it simple. I was originally wanting to attach it to the frame on the other side of the torque strut with some type of flat plate with a bolt welded onto it, but this was easier and there's plenty of room. Plus I had this welded piece of angle already lying around, it is the old upper motor mount I replaced earlier. It's bolted down directly to the battery rack which is VERY solidly welded to the frame. No strength worries there. There's still enough room on the battery rack for 12 cells when I move them up out of the trunk. I still have to remove the bracket to clean it up a little and paint it, but I needed to get the car running for the week. I'll paint it later.

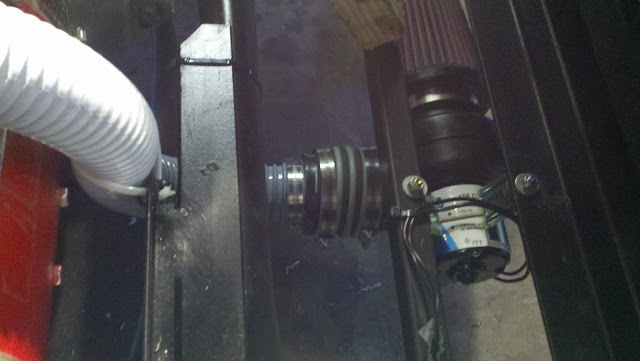

here's a few shots of the motor blower and hose routing. The blower is rubber mounted to the underside of the front battery racks.

|

| From 2011-10-23 mount |

|

| From 2011-10-23 mount |

|

| From 2011-10-23 mount |

I used another stock Saturn transmission torque strut just to keep it simple. I was originally wanting to attach it to the frame on the other side of the torque strut with some type of flat plate with a bolt welded onto it, but this was easier and there's plenty of room. Plus I had this welded piece of angle already lying around, it is the old upper motor mount I replaced earlier. It's bolted down directly to the battery rack which is VERY solidly welded to the frame. No strength worries there. There's still enough room on the battery rack for 12 cells when I move them up out of the trunk. I still have to remove the bracket to clean it up a little and paint it, but I needed to get the car running for the week. I'll paint it later.

here's a few shots of the motor blower and hose routing. The blower is rubber mounted to the underside of the front battery racks.

|

| From 2011-10-23 mount |

|

| From 2011-10-23 mount |

|

| From 2011-10-23 mount |

Friday, October 21, 2011

I'm legal!

so a month or so ago when I first got the car, I went to the DMV to start the registration (out of state car). At that time, they said I couldn't really do much without an official VIN inspection, but they could at least get it in the system under my name, and take my money... I told the worker at that time that it was an electric conversion, so he entered motive power as E. Which would obviously be verified later by the inspector, but I think it really helped my cause to have it entered this way from the get-go.

Anyway, yesterday I went back down there, got a one day pass to drive on the roads, and drove the car down. The inspection consisted of a DMV worker looking at the VIN number, checking a few boxes, and handing me back the paperwork. I then told her that it was electric, and asked her to change the motive power to "E" on her form so it would match what was in the computer (she hadn't even noticed, despite 'inspecting' something under the hood...). So... after a brief discussion where she informed me I was a little bit off to pay $7000 for batteries to build a car that could only go 50 miles (hard to argue on the surface, and I'm certainly not inclined to go into any deep discussion of the merits with her) she changed it to "E".

Lines were too long to go back inside and finish up the paperwork, so I made an appointment for this morning. Went back down this morning, verification in hand, mostly expecting them to tell me I had to go to an official smog referee or something since I shouldn't have to be smogged anymore. Instead, the counter worker typed in some info, charged me more money for registration (only paid transfer tax last time), and handed me a new set of license plates and registration stickers! Holy crap, I'm legal! Way easier than I was expecting.

Although I guess I should hold off judgement until I get my renewal next year and see if it says I have to get a smog check.

Anyway, yesterday I went back down there, got a one day pass to drive on the roads, and drove the car down. The inspection consisted of a DMV worker looking at the VIN number, checking a few boxes, and handing me back the paperwork. I then told her that it was electric, and asked her to change the motive power to "E" on her form so it would match what was in the computer (she hadn't even noticed, despite 'inspecting' something under the hood...). So... after a brief discussion where she informed me I was a little bit off to pay $7000 for batteries to build a car that could only go 50 miles (hard to argue on the surface, and I'm certainly not inclined to go into any deep discussion of the merits with her) she changed it to "E".

Lines were too long to go back inside and finish up the paperwork, so I made an appointment for this morning. Went back down this morning, verification in hand, mostly expecting them to tell me I had to go to an official smog referee or something since I shouldn't have to be smogged anymore. Instead, the counter worker typed in some info, charged me more money for registration (only paid transfer tax last time), and handed me a new set of license plates and registration stickers! Holy crap, I'm legal! Way easier than I was expecting.

Although I guess I should hold off judgement until I get my renewal next year and see if it says I have to get a smog check.

Wednesday, October 19, 2011

It's Alive!!

it's alive!

an hour here, an hour there, and over the last few days I've gotten all the wiring back in place. I used a light smear of NO-OX ID "A Special" on the high voltage cable connections. When I was all done and ready to test, I went back and checked and rechecked ALL my wiring a few times. With the high voltage breaker off, I turned on the key and checked all the 12v systems. All good! I have not yet put in the motor fan, and pulled the fuse for the controller fans (just so I could hear any problems a bit easier), the only sound was the contactor engaging, and the vacuum pump pressurizing. 12v where it should be, good to go! Power off, breaker on, ready for the real deal. Here's the final look of the component shelf all wired up, pretty much looks like it did before. I moved stuff around a little, but just detail work. The basics didn't change.

I did my first full voltage test (well, almost full, the batteries are all at 3.30v) with the wheels up. Good thing!! As soon as I turned on the key the motor spun up. simple problem, the throttle cable was not seated correctly in the housing at the potbox. Still, I sort of thought there was some kind of safety that wouldn't let the controller come on if the throttle was on. guess that's only on the new computer controlled fancy controllers (this is a Logisystems 750a). OK, try again... key on, nothing but the vacuum pump. Yeah! I voltmetered a few spots and everything was looking good. 12v where it should be, 158v where it should be! I blipped the potbox by hand, the motor spun up. Nice!

In the car I worked the throttle a bit and ran through the gears. All good. Checked the DC/DC output. good. Checked the heater. yup, it heats. Checked all the lights. yup, everything works. No more stalling, time to drop the car off the jackstands and try it out. I rolled backwards down the driveway into the street on gravity and I put it in second gear. clutch in, some throttle, I could hear the motor spin up. Clutch slowly out, and I'm off! Very cool. I ended up doing around 5 miles around the neighborhood, it ran smooth as long as I started with the clutch. Trying to start out in gear without the clutch was jerky, and without the final torsion mount installed on the motor yet I don't want to risk it so I stuck with using the clutch the whole time.

Successful first test, it's currently non-op'd at the DMV so I've got to go back down there and get it all legal before I drive it anymore. I'm going to start that process tomorrow morning, not sure how hard it will be. I know it will involve a smog referee inspection at a minimum, not sure what all they will need to see.

Here's one more picture of it in the garage plugged in and charging.

an hour here, an hour there, and over the last few days I've gotten all the wiring back in place. I used a light smear of NO-OX ID "A Special" on the high voltage cable connections. When I was all done and ready to test, I went back and checked and rechecked ALL my wiring a few times. With the high voltage breaker off, I turned on the key and checked all the 12v systems. All good! I have not yet put in the motor fan, and pulled the fuse for the controller fans (just so I could hear any problems a bit easier), the only sound was the contactor engaging, and the vacuum pump pressurizing. 12v where it should be, good to go! Power off, breaker on, ready for the real deal. Here's the final look of the component shelf all wired up, pretty much looks like it did before. I moved stuff around a little, but just detail work. The basics didn't change.

|

| From 2011-10-19 first test |

I did my first full voltage test (well, almost full, the batteries are all at 3.30v) with the wheels up. Good thing!! As soon as I turned on the key the motor spun up. simple problem, the throttle cable was not seated correctly in the housing at the potbox. Still, I sort of thought there was some kind of safety that wouldn't let the controller come on if the throttle was on. guess that's only on the new computer controlled fancy controllers (this is a Logisystems 750a). OK, try again... key on, nothing but the vacuum pump. Yeah! I voltmetered a few spots and everything was looking good. 12v where it should be, 158v where it should be! I blipped the potbox by hand, the motor spun up. Nice!

In the car I worked the throttle a bit and ran through the gears. All good. Checked the DC/DC output. good. Checked the heater. yup, it heats. Checked all the lights. yup, everything works. No more stalling, time to drop the car off the jackstands and try it out. I rolled backwards down the driveway into the street on gravity and I put it in second gear. clutch in, some throttle, I could hear the motor spin up. Clutch slowly out, and I'm off! Very cool. I ended up doing around 5 miles around the neighborhood, it ran smooth as long as I started with the clutch. Trying to start out in gear without the clutch was jerky, and without the final torsion mount installed on the motor yet I don't want to risk it so I stuck with using the clutch the whole time.

Successful first test, it's currently non-op'd at the DMV so I've got to go back down there and get it all legal before I drive it anymore. I'm going to start that process tomorrow morning, not sure how hard it will be. I know it will involve a smog referee inspection at a minimum, not sure what all they will need to see.

Here's one more picture of it in the garage plugged in and charging.

|

| From 2011-10-19 first test |

Tuesday, October 11, 2011

getting stuff done

got a bunch of little things done today, one of them was replacing the clutch master cylinder/slave assembly (it's sold as a pre-bled kit). The old one had the hydraulic hose replaced with fuel line! No wonder it didn't work... I can't actually test it yet, but it has a good feel now. It is certainly possible that something more major is wrong and the hose was replaced with fuel line just to stop it from leaking, knowing it doesn't work anyway. I won't really know about the clutch till I get it running.

Also finished up the passenger side mount tonight, basically just two pieces of angle that will be welded back to back. this is the piece that connects the old frame bracket (with the rubber mounts on it) to the new motor bracket. Here it is drilled, trimmed (that's my super accurate cutout for the motor blower and bolted together with tiny little screws. I'm gonna take it down to someone to weld it together tomorrow. It will not be seen, so I'm not concerned about how it looks...

I also got moving on the wiring. Mostly things are going back where they were, with some very minor changes. I am making sure that the space for the controller is large enough to fit any of the main contenders I'm considering upgrading to. They are (in no particular order) the Soliton Jr, Synkromotive, Zilla Z1K-LV (which includes mounting the Hairball) and the WarP Drive. No amount of moving stuff around would allow the Soliton1 to fit, but it's out of my budget (and needs) anyway.

Also spent some time figuring out how to route the blower hose, and where to mount the actual blower. It's going to mount nicely under the front battery rack, totally out of the way of anything. I have not mounted it yet, but at least I know where it will go. progress!

Also finished up the passenger side mount tonight, basically just two pieces of angle that will be welded back to back. this is the piece that connects the old frame bracket (with the rubber mounts on it) to the new motor bracket. Here it is drilled, trimmed (that's my super accurate cutout for the motor blower and bolted together with tiny little screws. I'm gonna take it down to someone to weld it together tomorrow. It will not be seen, so I'm not concerned about how it looks...

|

| From 2011-10-11 |

I also got moving on the wiring. Mostly things are going back where they were, with some very minor changes. I am making sure that the space for the controller is large enough to fit any of the main contenders I'm considering upgrading to. They are (in no particular order) the Soliton Jr, Synkromotive, Zilla Z1K-LV (which includes mounting the Hairball) and the WarP Drive. No amount of moving stuff around would allow the Soliton1 to fit, but it's out of my budget (and needs) anyway.

|

| From 2011-10-11 |

Also spent some time figuring out how to route the blower hose, and where to mount the actual blower. It's going to mount nicely under the front battery rack, totally out of the way of anything. I have not mounted it yet, but at least I know where it will go. progress!

Saturday, October 8, 2011

motor/trans back in car

Got the motor/trans back in the car, here are a few pics from the last few days...

here's the inside of the trans when I split it apart. Not too bad, a bit greasy. It cleaned up nicely, but I forgot to take a picture of it looking clean.

here we are dropping the motor in. You can see the new endplate on the CE side, it is an off the shelf bolt on (many bolt hole options) mounting plate with a foot. I like that better than the clamp that was on there before. I had measured the angle of tilt that ended up working to pull the motor out, and set it to that before starting. Motor/trans dropped right in with the help of some guiding hands.

this is more or less the motor's final resting spot. you can see the strap up to the hoist still holding up the motor end, the string tied between the strut towers, and the angle gauge. I still need to make the final connection between the new end plate and the existing rubber mounts which will be simple, two angles welded together. I can cut and fab the parts, but will have to take them to someone to be welded together. Oh, you can see the intake cover on the motor for the blower in this pic too. It does not enter the motor in the most ideal spot from a mounting/routing point of view, but it will work fine.

here's the inside of the trans when I split it apart. Not too bad, a bit greasy. It cleaned up nicely, but I forgot to take a picture of it looking clean.

|

| From 2011-10-07 motor install |

|

| From 2011-10-07 motor install |

this is more or less the motor's final resting spot. you can see the strap up to the hoist still holding up the motor end, the string tied between the strut towers, and the angle gauge. I still need to make the final connection between the new end plate and the existing rubber mounts which will be simple, two angles welded together. I can cut and fab the parts, but will have to take them to someone to be welded together. Oh, you can see the intake cover on the motor for the blower in this pic too. It does not enter the motor in the most ideal spot from a mounting/routing point of view, but it will work fine.

|

| From 2011-10-07 motor install |

Thursday, October 6, 2011

reassembly

Got the motor/trans mated together last night, everything looks good!

After it was reassembled I did a quick 12v spin and it was nice and smooth. I also received a box of parts from EVSource.com. Motor blower kit and rear motor mount. It looks like their prefabbed mount will be pretty close right out of the box, so I decided to buy and modify it rather than have one built locally from scratch. I will still need to have the torsion mount made after it's all installed though.

No pics/video of the reassembly process, but nothing too exciting happened. You've seen one clutch you've seen them all!

I've got some cutting to do, and need to go buy a new blade for my jigsaw before I can start. The garage could use a little organizing, cleaning, and sweeping before rolling the car back in as well.

After it was reassembled I did a quick 12v spin and it was nice and smooth. I also received a box of parts from EVSource.com. Motor blower kit and rear motor mount. It looks like their prefabbed mount will be pretty close right out of the box, so I decided to buy and modify it rather than have one built locally from scratch. I will still need to have the torsion mount made after it's all installed though.

No pics/video of the reassembly process, but nothing too exciting happened. You've seen one clutch you've seen them all!

I've got some cutting to do, and need to go buy a new blade for my jigsaw before I can start. The garage could use a little organizing, cleaning, and sweeping before rolling the car back in as well.

Tuesday, October 4, 2011

splitting motor/trans

So far upon disassembly, everything looks great. I haven't found anything I need to replace yet. Even the clutch disc looks new. Which I guess isn't surprising since the previous owner said the clutch didn't work, so the disc essentially was used as a fixed coupler. There is a slight runout on the flywheel (which has the ring gear removed, btw), maybe .007" at the most (crude measurement with calipers), but I don't feel any vibration in the motor when spun up on 12v with just the flywheel attached. And there's zero wobble, nice and flat. I don't plan on removing the flywheel since that would potentially open up a whole can of worms regarding the coupler, and since the motor and everything looks fine I see no reason to anyway.

I've got a lot of degreasing to do (inside the bellhousing, and the outside of the whole trans) then it will be on to reassembly!

I've got a lot of degreasing to do (inside the bellhousing, and the outside of the whole trans) then it will be on to reassembly!

Sunday, October 2, 2011

Got the motor out!

Finally got the motor out!!! It took me a week to find the time to do one hour of work…

Here’s the obligatory ‘motor hovering over the car’ shot with my helper/hoist operator,

a few more of the motor/trans, and empty car.

Hope to have the motor/trans separated cleaned and inspected in the next few days, then I’ll see what I need to do in order to get it back together.

Here’s the obligatory ‘motor hovering over the car’ shot with my helper/hoist operator,

|

| From 2011-10-02 pulling motor |

a few more of the motor/trans, and empty car.

|

| From 2011-10-02 pulling motor |

|

| From 2011-10-02 pulling motor |

Hope to have the motor/trans separated cleaned and inspected in the next few days, then I’ll see what I need to do in order to get it back together.

Wednesday, September 28, 2011

motor mount thoughts

On close inspection, it's clear I need to redesign the rear motor mount. Currently, the rear mount (CE of the motor) is a beefy strap clamped around the end, then connected to the stock upper motor mount location. I don’t like this setup because a portion of the clamp is actually over the inlet screen, which is not well attached to the motor itself. This appears to be what actually damaged the motor. The clamp to screen was solid, but the clamp and screen rotated together on the motor and damaged the posts and connector when everything broke and rotated. I see two options here. Either a) modify/remove the screen so the clamp is directly on the motor or b) replace the clamp with a simple CE bolt on plate that connects to the same mounting point. Either way I’ll add a lower torque bar to reduce motor rotation. This will require welding a tab to the frame, once I get the motor back in I’ll have to tow it to a shop to have that done. I’m sure the torque bar itself will be enough to solve the problem.

Friday, September 23, 2011

pics of motor damage

A bit more progress today, I pulled out all the components mounted over the motor. First I made a good wiring diagram, then started disconnecting and labeling everything. It was a shame to pull it all apart, it was wired really cleanly! Anyway, with the tray and components out of the way, I could get a good look at the motor.

In the closeup below, you can see the damage. The closer I look, the better it seems! It looks like it possibly is just that the metal screen rotated and pushed up against the terminals and the plastic connector. It broke the connector out of the case, but the terminals actually look decent, just the plastic insulators got thrashed. It also really shows how far up the motor twisted. It pulled the rubber motor mount clean apart on the right side.

below are a few photo’s showing the ripped apart CV joint (which sprayed grease on everything near it!) and the lower torn trans mount. It also completely separated.

so far so good!

|

| From 2011-09-23 damage |

|

| From 2011-09-23 damage |

In the closeup below, you can see the damage. The closer I look, the better it seems! It looks like it possibly is just that the metal screen rotated and pushed up against the terminals and the plastic connector. It broke the connector out of the case, but the terminals actually look decent, just the plastic insulators got thrashed. It also really shows how far up the motor twisted. It pulled the rubber motor mount clean apart on the right side.

|

| From 2011-09-23 damage |

|

| From 2011-09-23 damage |

|

| From 2011-09-23 damage |

|

| From 2011-09-23 damage |

below are a few photo’s showing the ripped apart CV joint (which sprayed grease on everything near it!) and the lower torn trans mount. It also completely separated.

|

| From 2011-09-23 damage |

|

| From 2011-09-23 damage |

so far so good!

Thursday, September 22, 2011

Arriving home!

I had the car transported since it was a non-runner, it was delivered on a huge transporter right to our doorstep! What service.Here’s my girls trying to figure out which one is our new car…

and here they are trying to figure out where to hook the winch line. (yes, the wheels are chocked...)

I was able to pull it up the hill into the garage without problem, prior to it arriving I had installed a 1/2" anchor bolt in the garage floor and bought a hand winch to pull the car up our steep driveway. I had one kid in the driver’s seat covering the brake, and the other in the passenger seat ready to yank up the e-brake on a moments notice! They took their jobs VERY seriously. Alas, there was no drama, it just pulled right up and in.

|

| From 2011-09-22 delivery |

|

| From 2011-09-22 delivery |

I was able to pull it up the hill into the garage without problem, prior to it arriving I had installed a 1/2" anchor bolt in the garage floor and bought a hand winch to pull the car up our steep driveway. I had one kid in the driver’s seat covering the brake, and the other in the passenger seat ready to yank up the e-brake on a moments notice! They took their jobs VERY seriously. Alas, there was no drama, it just pulled right up and in.

I fooled around with it for a little while, mostly making a wiring diagram and trying to figure out how everything was wired up. I also pulled the hood off, but that was the extent of my actual ‘work’ tonight. Most of the components have to come out in order to pull the motor (and replace the component shelf that was broken when the motor jacked up) so I want to make sure I’ve got a good complete wiring diagram before moving forward. Here’s a few ‘before’ pics of it nice and snug in the garage.

|

| From 2011-09-22 delivery |

|

| From 2011-09-22 delivery |

|

| From 2011-09-22 delivery |

In the beginning...

I just purchased an electric car! This blog will chronicle the rebuilding of this car, as well as an ongoing report of life with a 100% electric vehicle.

This particular car, a 1995 Saturn SL2 4 door sedan, was converted to electric a few years ago. The initial conversion was done with lead acid batteries, and as far as I can tell was a very quality conversion. It was then sold to another owner who drove it for a while, then swapped the lead batteries for Lithium Ion batteries (LiFePO4). This is a massive improvement, basically a similar chemistry to what is in the Leaf and Tesla. The car then had a serious problem where the motor mounts broke allowing the whole motor/trans to swing up and do some serious damage to the mounting structure as well as the CV joints.

I bought the car in non-working condition with the batteries and all. A solid base for a new project, basically an electric car 'fixer-upper' that should not take too long to get back on the road. It will then be a series of ongoing smaller projects to improve the car once it's back together and being used as my daily driver.

Subscribe to:

Posts (Atom)