it's alive!

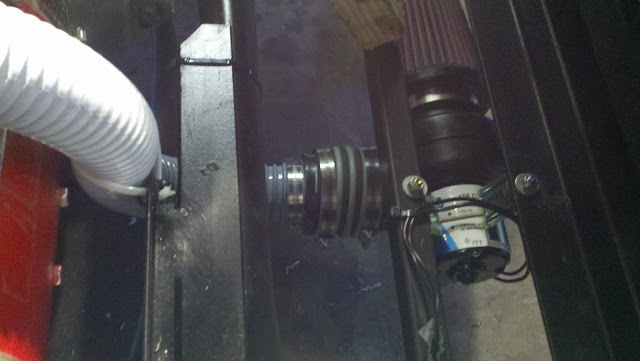

an hour here, an hour there, and over the last few days I've gotten all the wiring back in place. I used a light smear of NO-OX ID "A Special" on the high voltage cable connections. When I was all done and ready to test, I went back and checked and rechecked ALL my wiring a few times. With the high voltage breaker off, I turned on the key and checked all the 12v systems. All good! I have not yet put in the motor fan, and pulled the fuse for the controller fans (just so I could hear any problems a bit easier), the only sound was the contactor engaging, and the vacuum pump pressurizing. 12v where it should be, good to go! Power off, breaker on, ready for the real deal. Here's the final look of the component shelf all wired up, pretty much looks like it did before. I moved stuff around a little, but just detail work. The basics didn't change.

I did my first full voltage test (well, almost full, the batteries are all at 3.30v) with the wheels up. Good thing!! As soon as I turned on the key the motor spun up. simple problem, the throttle cable was not seated correctly in the housing at the potbox. Still, I sort of thought there was some kind of safety that wouldn't let the controller come on if the throttle was on. guess that's only on the new computer controlled fancy controllers (this is a Logisystems 750a). OK, try again... key on, nothing but the vacuum pump. Yeah! I voltmetered a few spots and everything was looking good. 12v where it should be, 158v where it should be! I blipped the potbox by hand, the motor spun up. Nice!

In the car I worked the throttle a bit and ran through the gears. All good. Checked the DC/DC output. good. Checked the heater. yup, it heats. Checked all the lights. yup, everything works. No more stalling, time to drop the car off the jackstands and try it out. I rolled backwards down the driveway into the street on gravity and I put it in second gear. clutch in, some throttle, I could hear the motor spin up. Clutch slowly out, and I'm off! Very cool. I ended up doing around 5 miles around the neighborhood, it ran smooth as long as I started with the clutch. Trying to start out in gear without the clutch was jerky, and without the final torsion mount installed on the motor yet I don't want to risk it so I stuck with using the clutch the whole time.

Successful first test, it's currently non-op'd at the DMV so I've got to go back down there and get it all legal before I drive it anymore. I'm going to start that process tomorrow morning, not sure how hard it will be. I know it will involve a smog referee inspection at a minimum, not sure what all they will need to see.

Here's one more picture of it in the garage plugged in and charging.