here's a bunch of photo's from the weekend:

the old potbox

|

| From 2011-11-06 synkro |

the custom cable holder. just a simple piece of sheetmetal bent and drilled to hold the nub on the end of the cable. the holes in the TPS bracket are already the perfect size for this, so the cable is sandwiched between the arm and this little bracket. each side holds the nub, and it's free to rotate. simple and effective.

|

| From 2011-11-06 synkro |

here is the arm with the cable attached

|

| From 2011-11-06 synkro |

here's the whole throttle assembly attached. it is truly a piece of beauty! I'm not sure my car is worthy of such a nice part. it certainly deserves a nicer mounting bracket...

|

| From 2011-11-06 synkro |

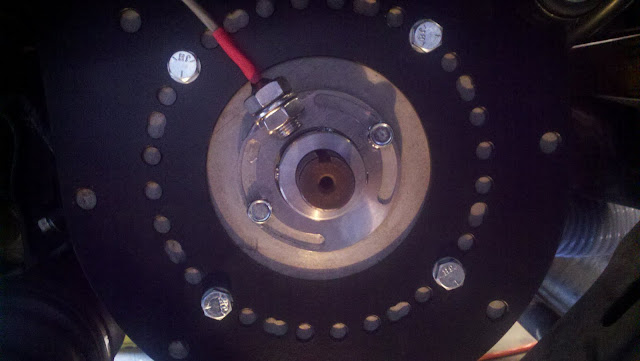

here is the Netgain speed sensor. Very easy to install, the only challenging part was that my motor endshaft had just enough surface rust on it to keep the collar from sliding on. i had to remove the wheel to get better access, then lightly sand the shaft with some 600 grit paper to smooth it up enough to install the collar. although looking at this photo, i can see that I accidentally lined up one of the set screws with the keyway. dang, I'll have to get back in there and rotate it a bit.

|

| From 2011-11-06 synkro |

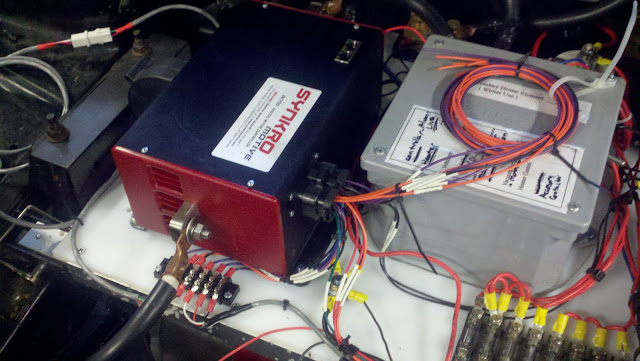

here's the controller! the small terminal block right in front of it holds the connections to the speed sensor and the throttle. The bundle of wires on my heater controls box are the extra wires not needed for my installation (reversing contactor controls, various outputs, etc). Not sure what to do with those yet... all the wires plug into the controller with a nice waterproof connector, which seems a little odd since the controller itself is obviously not waterproof. Anyway, the wires were all nice and long, easy to route and connect up.

|

| From 2011-11-06 synkro |

here's the backside. Yes, I'm using a second EV200 contactor for my high voltage accessories. Yes, it's overkill.

|

| From 2011-11-06 synkro |

and the overall shot. this is pretty much finished up. You can see the 12v relay next to the terminal strips, that's for the vacuum pump. The loose wires heading down in the front of the photo are going to the motor blower. I still need to clean up and re-route those wires.

|

| From 2011-11-06 synkro |

That's it for now. Hopefully it will stay this way for a little while. I do need to put on some of the plastic bits back on up front to get it ready for the rain, but it's basically ready to be my daily driver now.

No comments:

Post a Comment